Automotive Injection Molding High-precision complex parts, faster validation, and reliable PPAP

TL;DR

-

What we do: Electric vehicle (EV) and internal combustion engine (ICE) powertrain, thermal, braking, fluid systems, interiors

-

Why Kaysun: IATF 16949:2016, PPAP/APQP, scientific molding, DfM, mold flow analysis

-

Outcomes: Lighter parts, tighter tolerances, fewer defects, and shorter launches

Automotive injection molding provides lighter, stronger, and more reliable plastic parts for Electric Vehicle (EV) and Internal Combustion Engine (ICE) vehicles. Kaysun partners with automotive OEMs to solve complex design and manufacturing challenges (material selection, DfM, mold flow, tooling, and validation) so consistent, reliable products go to market.

Choosing the Right Automotive Injection Molder

The best automotive injection molders are focused on helping OEMs seamlessly meet strict compliance regulations and execute go-to-market strategies. Each partnership is built around early engineering engagement, process transparency, and validation discipline backed by:

- IATF 16949:2016 certified quality systems built for traceability, layered audits, and continuous improvement

- Robust PPAP/APQP and PFMEA processes that provide part validation confidence and launch predictability

- Early DfM and mold flow collaboration to mitigate tooling risk, compress development timelines, and optimize part performance

- Tooling agility supported by an established toolbuilder network enables rapid engineering changes, in-house adjustments, and effective preventive maintenance

Related Resources

Gas or Electric: Do Vehicle Power Sources Impact Automotive Plastics Selection?

Advanced Plastics Make Vehicles Efficient, Affordable & Attractive

4 Automotive Plastic Parts Trends That are Redefining the Industry

How Automotive Manufacturers Should Evaluate Complex Injection Molders

Certified Automotive Injection Molding Company

Kaysun is an IATF 16949:2016-certified automotive injection molding company with mature PPAP/APQP processes, advanced metrology & in-house testing/quality assurance, and program management aligned with OEM and Tier-1 expectations.

Automotive Plastic Injection

Molding Capabilities

Engineering & Materials Expertise

- Engineering-grade resin selection to balance high heat, chemical resistance, and fatigue (PA, PPS, PEEK, PC/ABS, TPE) in harsh environments

- Metal-to-plastic conversion guidance on weight, cost, corrosion, and Noise/Vibration/Harshness (NVH) reduction strategies

- DfM reviews optimize ribs, draft angles, gate locations, and knit line control

- Mold flow analysis validates tool performance by simulating fill, pack, cooling, and warp

Process Control

- Scientific molding uses sensor-based data to precisely replicate ideal shot conditions across all cavities

- In-process monitoring, closed-loop adjustments, and cavity pressure curves ensure molding consistency and part integrity throughout production

- Centralized material handling and automation improve process repeatability and waste reduction

Quality & Compliance

- Tolerances to ±0.001" are supported through precision tooling and validated process management

- In-house quality lab and advanced metrology including CT scanning, CMM, vision, leak/functional testing verify internal and external part quality

Metal-to-Plastic Conversion for Lightweighting & Cost Effectiveness

- Engineered thermoplastics replace metal to reduce weight while maintaining structural and functional performance

- Plastic-specific design facilitates part consolidation and achieves complex geometries that simplify assemblies

- Reduced mass supports fuel efficiency, emissions compliance, and EV range targets

- Corrosion-resistant materials improve durability in harsh automotive environments

- Integrated features eliminate secondary operations, lowering total manufacturing cost

- Advanced materials and quality controls validate performance under heat, vibration, and chemical exposure

Related Resources

Converting Metal Automotive Components to Plastic: A Manufacturer’s Guide

3 Steps to Converting Metal Automotive Components To Plastic

Converting Metal Automotive Components To Plastic: A Manufacturer’s Guide

Plastics In Automotive Applications: Replacing Steel With Composites

Automotive Applications We Support

- Powertrain and EV system parts demand chemical resistance, complex geometries, and electrical isolation

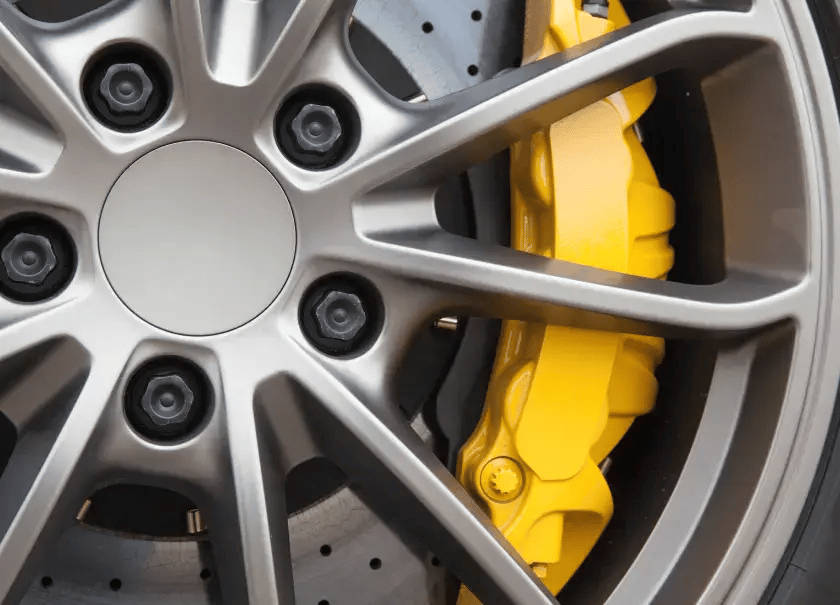

- Braking and safety-critical components call for precise tolerances, consistent shot-to-shot replication, and full traceability

- Interior and structural parts benefit from part consolidation, aesthetic precision, and strength-to-weight efficiency

- Thermal and cooling components require high-temperature resins, dimensional stability, and fluid sealing

Real-World Results

Sunroof Front Frame

Challenge:

OEM struggled with part warp and flash issues when transitioning a metal component to plastic

Solution Highlights:

- Automated work cells with robotic insert loading (9 metal inserts per part)

- “No flash” tooling using spring-loaded components

- Molded-in clip features and rigorous QA

- Custom returnable packaging program

Impact:

Resolved previous supplier's warping issues, achieved successful metal-to-plastic conversion, reduced weight, and ensured zero flash with high repeatability

Belt Tensioning Pulley Assembly

Challenge:

Replace metal part to reduce weight and cost, while meeting tight noise and dimensional tolerances

Solution Highlights:

- Early design collaboration using DFM and scientific molding

- 10-gate system with pressure-controlled valve gates for roundness

- Molded-in bearing insert replaced secondary assembly

Impact:

Achieved perfect roundness, cut production costs, and maintained performance specs for a critical serpentine belt component

Heavy Truck Braking Valve Component

Challenge:

Previous molders failed to balance durability and straightness in compressed-air brake component

Solution Highlights:

- Tested 15+ materials for optimal fit

- Design of Experiments (DoE) used to refine gating and temperature profiles

- Tooling innovations (ring gating, variable shrinkage zones)

Impact:

Eliminated prior defects, enhanced dimensional consistency, and delivered a robust solution for a safety-critical part

Partners In Part Design & Material Selection

Early Engagement: How Automotive Injection Molders De-Risk Launch

Work with Kaysun engineers before tooling to reduce risk and accelerate production outcomes. We validate resin performance, optimize gating and venting, manage knit lines, and design efficient cooling paths. Leveraging our commitment to Engineered Excellence and expertise in Design for Manufacturability (DfM) and mold flow simulation, we help partners:

- Prevent warping and dimensional issues

- Shorten cycle times

- Minimize costly tool modifications

Related Resources

Precision Automotive Plastics: How Molders’ Material Expertise Benefits Components

How Engaging Molders in Design Reduces Automotive Part Costs and Risks

Plastics in Automotive Applications: Replacing Steel with Composites

Designing Plastic Parts for Complex Automotive Applications

Automotive Injection Molding FAQs

What is automotive injection molding?

A manufacturing process that produces precise, durable plastic components for vehicles using engineered resins, scientific molding, and validated quality controls.

How do I evaluate automotive injection molding companies?

Verify IATF 16949, PPAP maturity, DfM/mold flow capability, in-process monitoring, and relevant case studies.

What tolerances are typical?

Typical tolerances are geometry- and resin-dependent, but Kaysun routinely supports tight tolerances down to +/- 0.001 inch.

How does metal-to-plastic conversion help?

Reduces mass and parts count, improves corrosion resistance, and can lower total cost while meeting performance specs.

Do you support EV programs?

Yes, focusing on materials and designs for thermal management, sealing, electrical isolation, and fluid systems.

Does your company fit our ideal customer profile?

Complete the form to request a free consultation with our plastic engineering experts.