Consumer Market Injection Molding

Affordable. Reliable. On-demand. That’s what consumers expect, and what OEMs must deliver to fuel growth and protect brand reputation.

Whether it’s a simple personal care item or a high-precision component in a household appliance such as garbage disposals or faucet assemblies, success depends on precision-molded parts and a trusted injection molding partner. With Kaysun, Engineered Excellence ensures those expectations are consistently met at scale, and without compromise.

How Proven Injection Molders Benefit Consumer Market OEMs

Product quality is key for consumer market OEMs. However, aligning quality with performance must be done at a reasonable cost, or the market generally won’t bear the price point. Sensitivities around the economy cause consumer purchase confidence to ebb and flow.

These reasons drive OEM decisions about injection molding for consumer products and suppliers. Injection molding partners must be flexible enough to accommodate volume changes in demand, yet disciplined in structured lead times and meeting product launch deadlines — all often within a strict budget.

Injection molders with diverse capabilities provide expertise and value required to balance the competing priorities consumer market OEMs face. Experience matters. Specialization in sophisticated modeling programs and methodologies such as Design for Manufacturability (DfM), as well as strategic use of advanced processes like overmolding, and metal-to-plastic conversion help get stronger, better performing, and competitively priced products to market faster.

These resources provide deeper insights:

Value-Added Services

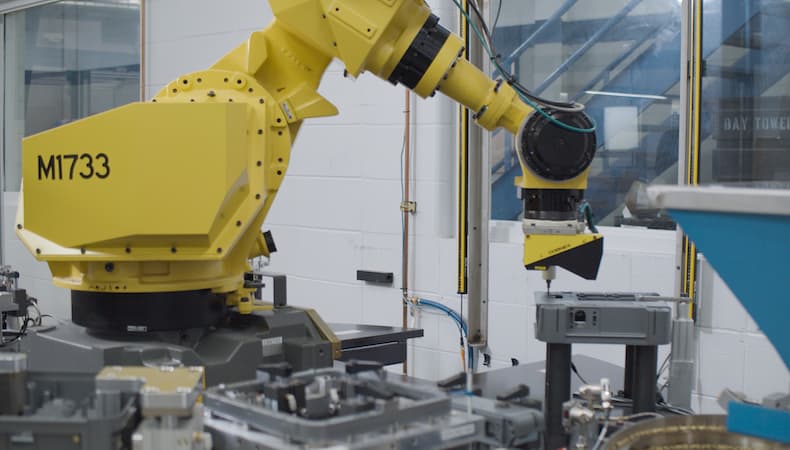

A custom injection molder maintains a broad view of any project. In addition to guiding decisions regarding the best design, tools, and processes there are post-molding considerations that impact quality, cost, and time to market.

OEMs working with vertically integrated suppliers reap the benefits of in-house value-added services like those provided by Kaysun:

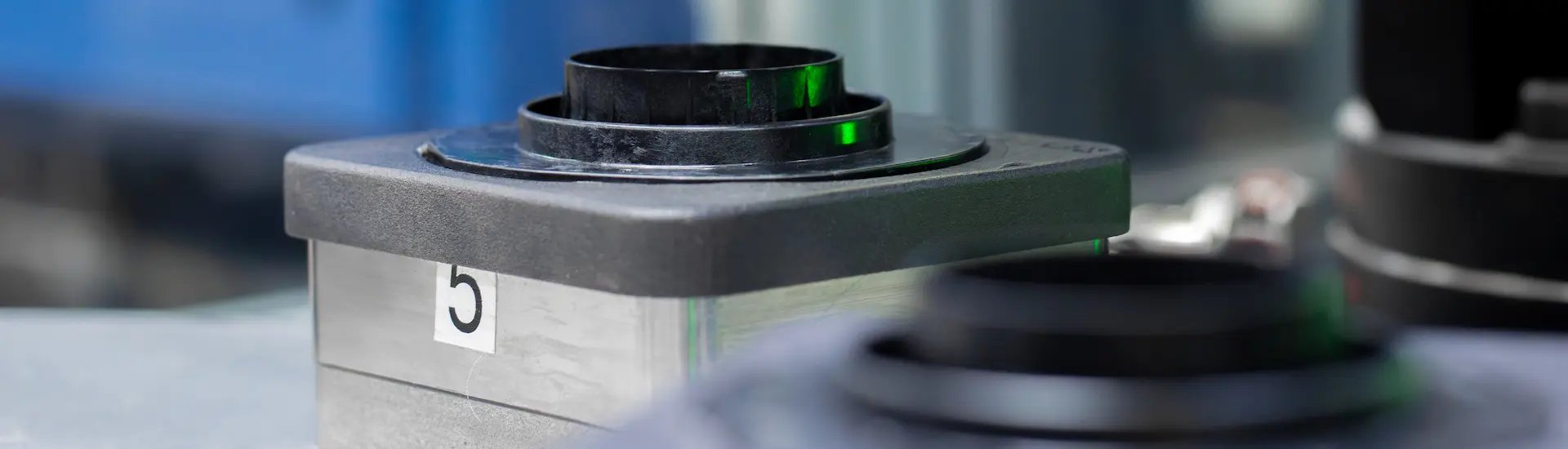

- Ultrasonic, spin, laser, and vibration welding

- Insert assembly

- Heat staking

- Plastic machining

- Potting/sealing

- Continuity testing

- Pad printing

- Labeling and identification

- Clean Infrared technology

- Thermal processing

- Packaging and assembly

Use these resources to objectively assess injection molder experience and credentials against your project needs or in comparison to offshoring opportunities:

Kaysun Blog

How Consumer Applications Benefit from Custom Injection Molding

The consumer market is vast. Injection molding plays an important role in determin…

READ MORE

4 Plastic Injection Molding Industry Trends Impacting Consumer Applications

Consumer applications are diverse. Simply having products on the market isn't enou…

READ MORE

What Consumer Market OEMs Need In a Full-Service Injection Molder

The consumer market is demanding. The need for and availability of products is lar…

READ MORE

Does your company fit our ideal customer profile?

Complete the form to request a free consultation with our plastic engineering experts.