Automotive Injection Molding Top Performance Through Engineered Excellence

The automotive industry is one of the most advanced manufacturing sectors in the United States. Reliance on injection molded plastic parts to improve safety, increase fuel efficiency, use alternate fuels and electricity, and reduce environmental impact continues to evolve in dynamic new directions.

Engineers from major automotive OEMs turn to custom automotive plastic injection molding experts such as Kaysun to solve their toughest design and engineering challenges—material selection and performance, design for manufacturability, prototyping, tool design, tolerances, quality control, and more.

These resources illustrate how an injection molder relationship is key to identifying and correcting defects before there are costly consequences:

Metal-to-Plastic Conversion Expertise for Quality, High-Performance Outcomes

With help from automotive injection molding companies, OEMs are embracing metal-to-plastic conversion as a proven solution for reducing vehicle weight and maximizing performance. Replacing heavy metal parts with lighter-weight but equally durable injection-molded plastic components helps meet fuel efficiency goals, emission requirements, and operational cost targets.

Using advanced technologies, best practices, and sophisticated quality control systems allows Kaysun to provide cost-effective metal-to-plastic conversion solutions for the toughest automotive engineering challenges.

The resources below explain the benefits of this innovative method and provide insights into how Kaysun helped customers achieve success:

Partners in Automotive Part Design & Material Selection: Kaysun’s Added Value

The demands on injection-molded plastic parts within automotive applications are great. Designs are increasingly complex and sometimes require tolerances as tight as +/- .001 inches. Harsh under-the-hood operating environments present extremes in temperatures, chemical exposure, and performance requirements. Designs and materials must stand up to the test.

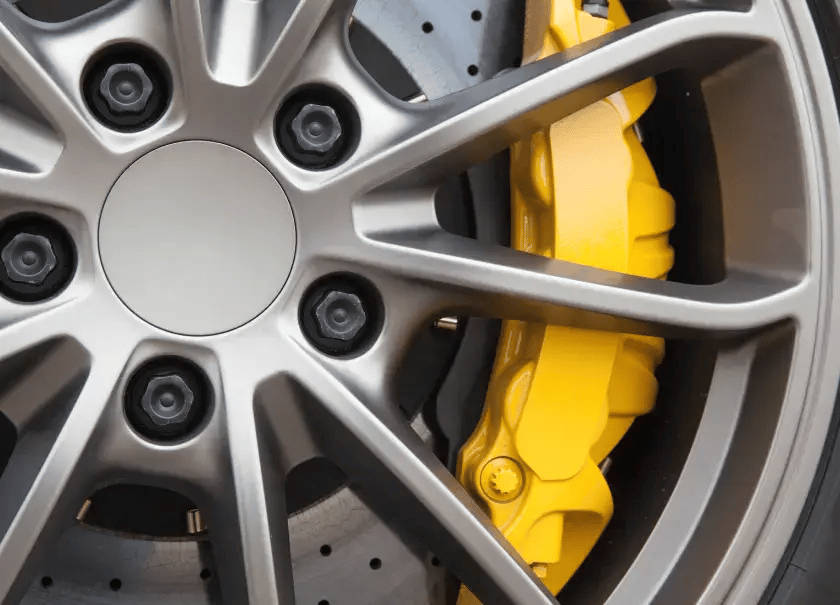

Currently, there are more than 25,000 plastic materials engineered to provide specific physical characteristics such as strength, flexibility, and temperature, corrosion, and/or UV resistance. Kaysun engineers share their in-depth materials science and injection molding expertise to help automotive OEMs select the best plastic for performance and operational goals. This is apparent when designing and manufacturing complex parts and components for vehicle braking systems, cooling systems, fuel delivery systems, and the powertrain.

These resources explore how getting Kaysun involved early in the process allows for the most efficient outcomes in design, material selection, and part performance:

Automotive Injection

Molding Experts

Kaysun is experienced in automotive product design, production & assembly. We hold IATF 16949:2016 certification, the quality management system standard for the automotive industry.

Kaysun Blog

Top 3 Custom Injection Molding Trends to Watch in 2025

Despite being considered more energy efficient and producing less waste than other…

READ MORE

Gas or Electric: Do Vehicle Power Sources Impact Automotive Plastics Selection?

Environmental protection and the legislation surrounding it have heightened people…

READ MORE

4 Automotive Plastic Parts Trends That Are Redefining the Industry

By 2024 the need for automotive plastics, parts, and innovations will push the val…

READ MORE

Does your company fit our ideal customer profile?

Complete the form to request a free consultation with our plastic engineering experts.