Plastic part design

Since 1975, the automotive industry has been under governmental mandate to improve the average fuel economy of cars and light trucks manufactured in the United States. The Corporate Average Fuel Economy (CAFE) standards, born out of the Arab Oil Embargo of the mid-70s, are still in effect today with recently added emphasis placed on further improving fuel economy, reducing greenhouse gases and saving people money at the gas pump.

To that end, the National Highway Traffic Safety Administration (NHTSA) and United States Environmental Protection Agency (EPA) have joined forces to develop and issue joint final rules for CAFE compliance that apply to consecutive five-year blocks of vehicle models. As rules and automobile efficiencies evolve, it begs the question of how automotive manufacturers will continue to successfully meet CAFE standards.

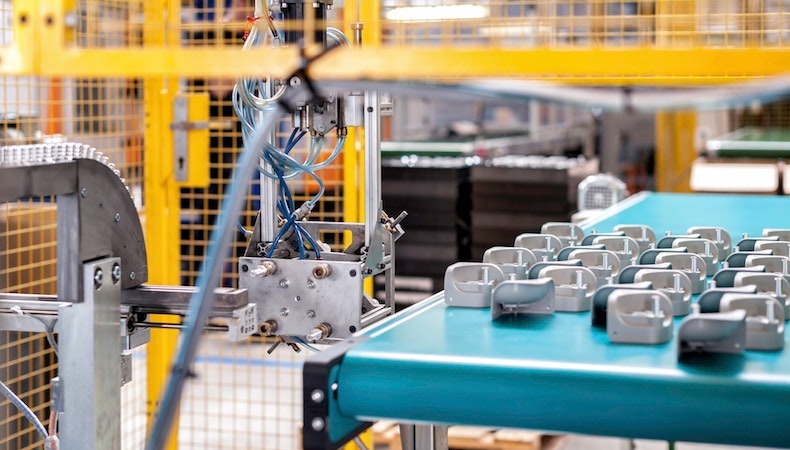

The answer partially lies in automobile lightweighting, meaning building vehicles that weigh less and, as a result, achieve better fuel economy and handling. Using injection molded plastic components instead of die cast metal parts present viable opportunities to lighten the vehicle weight, reduce engine strain and improve overall performance. Also, fewer metal parts equates to less rusting, landfill debris, and the resulting environmental hazards.

While swapping metal automotive parts for injection molded plastic components may sound relatively simple, in reality, it’s a complex engineering process. Designers need to understand the mechanical and structural differences between metal and plastic to determine how the materials will perform in end-user environments, and in which ways metal-to-plastic conversion will impact outcomes.

To do so, there are three critical steps design engineers need to follow:

Many manufacturers are turning to metal-to-plastic component conversion to comply with increased governmental mandates within the automotive industry. For more detailed information on the science and process behind converting automotive designs to plastic, read our new ebook, "Converting Metal Automotive Components to Plastic: A Guide for Manufacturers." Click the button below to download your free copy!

TL; DR: The 30-second Summary As manufacturing evolves, OEMs are focusing on quali…

READ MORE

TL; DR: The 30-second Summary Non-uniform walls create quality issues because of p…

READ MORE

In many complex industries, decisions about which injection molder to use for cust…

READ MORE