Plastic part design

It’s generally accepted that roughly 80% of a part’s total cost is determined during the design/development phase, and cannot be reduced – or is extremely difficult and expensive to change – once the design is finalized. However, by utilizing a Design for Manufacturability (DfM) approach and the specialized expertise of a plastics engineer, deliberate design decisions can be made to help manage/reduce total part and production costs.

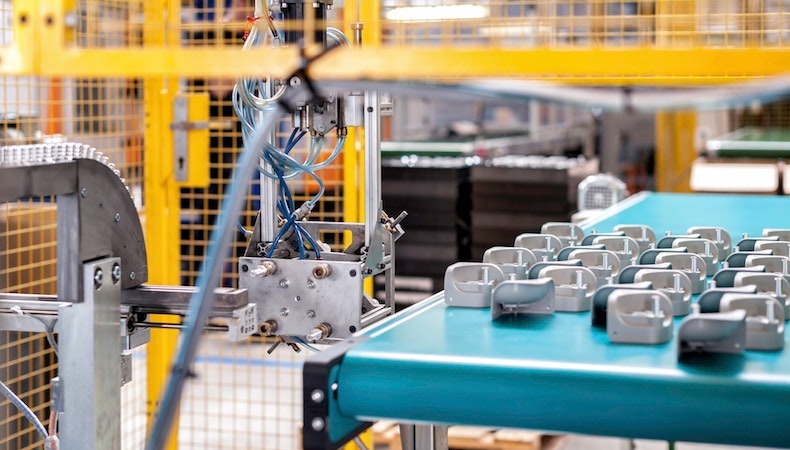

Product development is an area where the value of partnering with an injection molder with experience in DfM really shines. Specially trained DfM engineers come alongside the design team to evaluate the processes necessary to optimize all facets of manufacturing for a particular project, with in-depth scrutiny of:

Further, since DfM is based on project-specific details, the production and cost efficiencies are “real world” and can be readily applied to a project. Questions are answered upfront about:

For injection molded plastic parts and components, DfM is instrumental in informing design decisions well before they impact project quality and costs, including:

Designing a part with a focus on manufacturability is a proven strategy for reducing costs, preventing rework and improving time to market. The relationship manufacturers choose to pursue with an injection molder will dictate how well DfM is integrated into the process, and the level of collaboration between the two will define success.

Kaysun is committed to true partnerships, and we lend our expertise to every phase of a project including the most expensive part — tooling. Learn more in our eBook, Tooling Design for Injection Molding. Click the button below to access your copy now.

TL; DR: The 30-second Summary As manufacturing evolves, OEMs are focusing on quali…

READ MORE

TL; DR: The 30-second Summary Non-uniform walls create quality issues because of p…

READ MORE

In many complex industries, decisions about which injection molder to use for cust…

READ MORE