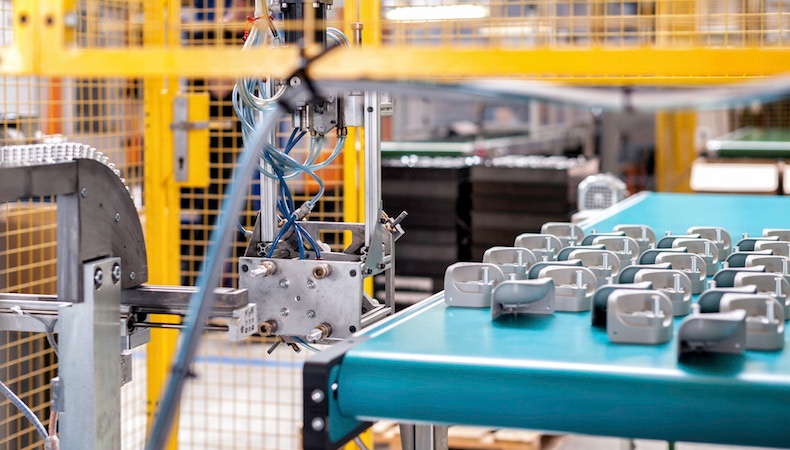

Injection molding process

Complex applications typically require custom injection molding solutions. It’s an investment OEMs are willing to make in order to get safe, effective parts and products to market — and one that provides value beyond price point if the injection molder is focused on Total Cost of Ownership (TCO) instead of per-part pricing.

Quotes from injection molders do more than convey project costs. They reveal how a molder scopes and approaches complex applications, and also reflect the level of thoroughness and quality an OEM can expect from a partnership.

It’s an important differentiator to keep in mind when comparing estimates. Per-part pricing can make for an attractive quote on its face, but expenses that weren’t considered or included in the quote can ultimately have OEMs facing diminishing returns. On the other hand, inclusive TCO-focused quotes may initially reflect higher bottom line costs, but the value brought to the project and injection molding partnership merits the spend.

An experienced injection molder such as Kaysun understands that a project encompasses the entire lifecycle of a part. Nuanced knowledge and capabilities are essential for both accurate quotes and desired custom injection molding outcomes. TCO considerations include:

All aspects of a project are influenced by design and engineering. Collaborating with specialized injection molding engineers such as Kaysun’s Design for Manufacturability (DfM) experts validates design and production feasibility, drives materials selection, maximizes part performance, and pinpoints and addresses modifications before they result in costly rework.

Optimizing DfM and related engineering goals works hand-in-hand with adhering to global sustainability standards and closer-to-home initiatives. Mindful design helps to minimize materials waste and scrap, reduce energy and water consumption, promote a smaller carbon footprint, and facilitate end-of-life part/product recycling or accelerated biodegradation.

Tooling is pivotal to consistent part production, and is often the most substantial cost consideration on custom injection molding projects. A molder with in-house tooling capabilities can accomplish pre-tooling design work that minimizes build-sample-evaluate-modify iterations. Likewise, having experts on-site to perform preventive maintenance on tools and related equipment pays for itself by ensuring a longer production lifespan, higher cycle rates, and less downtime.

Without a quality benchmark, injection molding accuracy and precision become moving targets. Parts are subject to inconsistencies, defects, and failure. Regulatory compliance could also be called into question. Costs could spiral without proper quality control. The Kaysun Quality Lab brings cutting-edge technology, testing equipment, and molding experts together under one roof to facilitate cross-departmental collaborations to verify pre-production readiness, in-production process stability, and product viability.

The more services an injection molder can provide in-house, the greater the benefit to the OEM in terms of cost-effective custom injection molding solutions. Kaysun’s breadth of value-added services promotes streamlined communication, higher product quality, lower cost, faster time to market, and rapid response time for re-design needs or market shifts.

Supply chain disruption has lengthy and expensive consequences. Molders that mitigate their risks through supply chain forecasting and mapping are ideal partners. OEMs that choose to shorten their supply chain through regionalized injection molding partnerships further improve flexibility and cost-effectiveness that ultimately translate to project savings.

Finding a custom injection molder that cultivates partnerships based on transparency from quoting through post-project support is a worthy investment for OEMs seeking competitive advantage.

How Injection Molder Partnerships Influence Project Costs explores the ins and outs of assessing and selecting a molder that fits your needs — and delivers so much more. Click below to download your guide!

TL;DR: The 30-second Summary As RJG phases out eDart by 2030, Kaysun is proactivel…

READ MORE

Injection-molded parts and products are staples for OEMs in industries ranging fro…

READ MORE

Injection molding is a versatile and precise process, making it ideal for OEMs tha…

READ MORE