Featured Blogs

Injection Molding in Wisconsin: What to Know

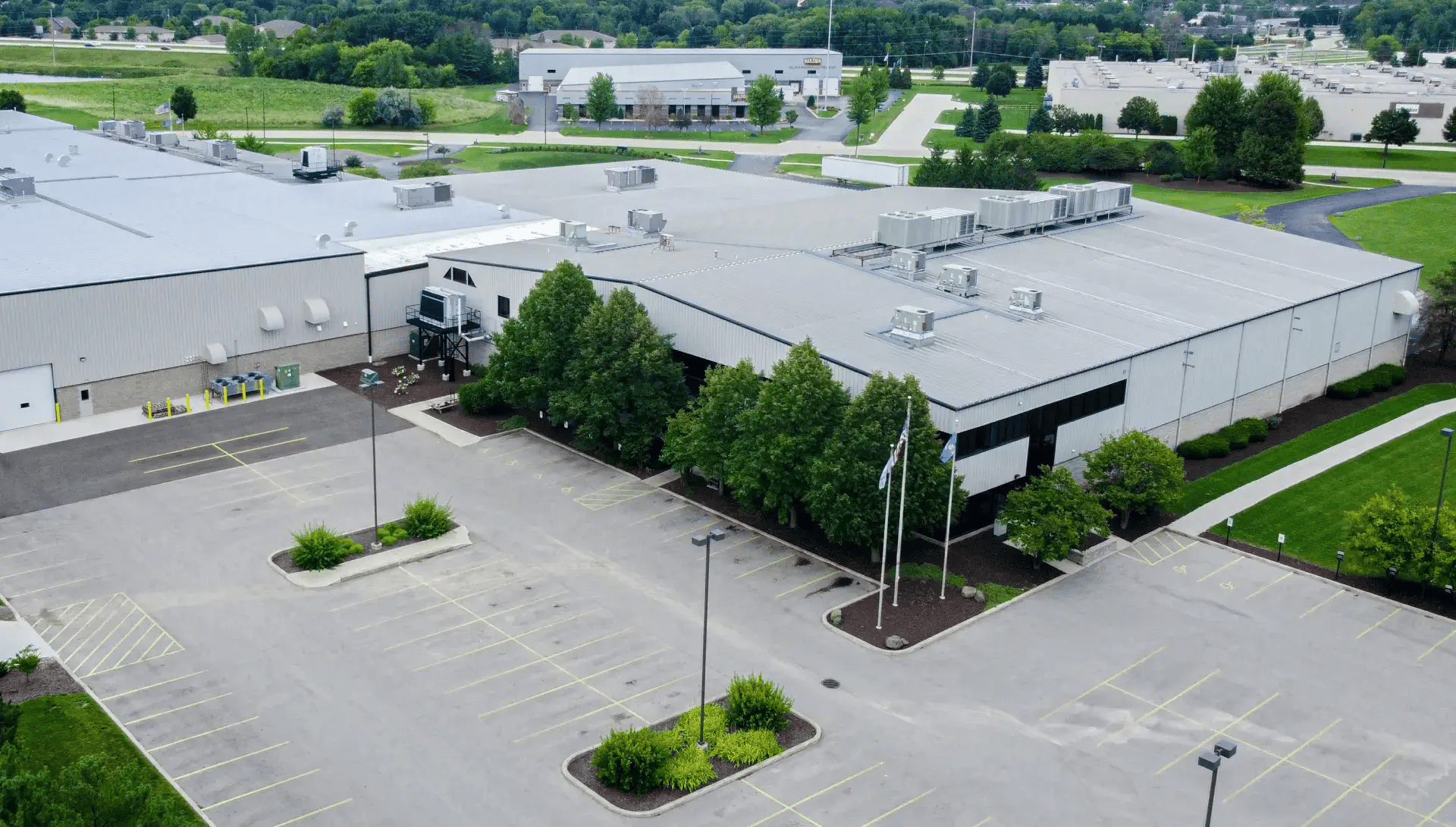

![kaysun-manitowoc-wisconsin-injection-molding-company]()

Injection Molding in Wisconsin: What to Know

TL; DR: The 30-second Summary If you’re looking for custom injection molding companies in Wisconsin, you’re tapping into one of …

READ MORE

4 Ways Reshoring Strengthens an OEM Supply Chain Strategy

4 Ways Reshoring Strengthens an OEM Supply Chain Strategy

READ MORE

Kaysun and Sodick: A Partnership Built on Precision, Proven by Performance

Kaysun and Sodick: A Partnership Built on Precision, Proven by Performance

READ MORE

A Reshoring Roadmap for OEMs Facing Tariff Pressures & Challenges

A Reshoring Roadmap for OEMs Facing Tariff Pressures & Challenges

READ MORE

Browse All Kaysun Articles

Kaysun Integrates AI on the Production Floor with RJG CoPilot

![production-floor]()

Kaysun Integrates AI on the Production Floor with RJG CoPilot

Industry 4.0 has made manufacturing more dynamic than ever before. Merging IoT, AI, …

READ MORE

Injection Molding Quotes: 5 Tips to Help Get Tooling Right

![toolmaker]()

Injection Molding Quotes: 5 Tips to Help Get Tooling Right

Few things impact injection-molded part quality as much as tooling design, materials…

READ MORE

4 Ways Reshoring Remains A Win for American Manufacturing

![]()

4 Ways Reshoring Remains A Win for American Manufacturing

International trade tensions have brought heightened awareness to reshoring. Recent …

READ MORE

Top 3 Custom Injection Molding Trends to Watch in 2025

![kaysun-team-in-meeting-with-data]()

Top 3 Custom Injection Molding Trends to Watch in 2025

Despite being considered more energy efficient and producing less waste than other m…

READ MORE

How Kaysun’s Culture of Sustainability Benefits OEMs and The Planet

![culture-of-injection-molding-sustainability]()

How Kaysun’s Culture of Sustainability Benefits OEMs and The Planet

Injection-molded parts and products are staples for OEMs in industries ranging from …

READ MORE

The Impact of Non-Uniform Injection Molding Wall Thickness

![injection-molded-parts]()

The Impact of Non-Uniform Injection Molding Wall Thickness

Shrink rates for plastic parts vary depending on the materials used and the uniformi…

READ MORE