Plastic part design

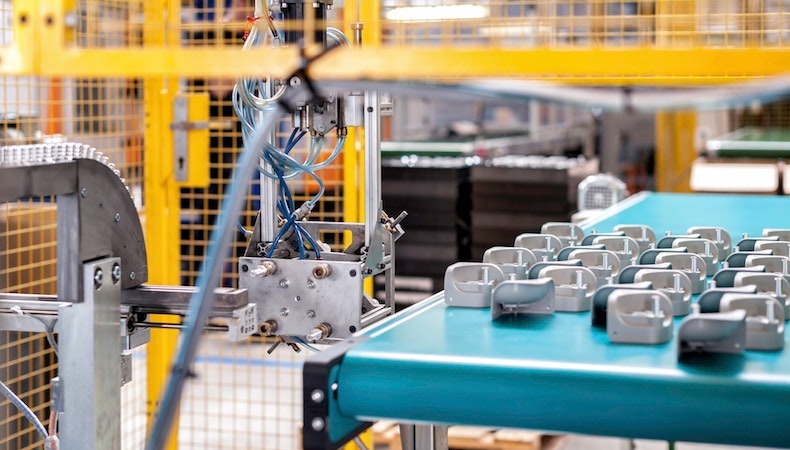

Little things matter when it comes to overall efficiency, productivity and quality. Of course, having the best equipment and technologies, materials, know-how and training is a given. But efficiency and productivity are generally always enhanced when injection molders and their customers know each other well as partners and work together as a team. They share the same strategies. Each knows how the other thinks and operates. The relationship deepens over the long term because they know they are stronger together.

When a customer decides to partner with a high-quality injection molder, great things can happen like shorter project lead times. Depending on the size and complexity of the project, as much as two weeks can be saved for a simple part or many months for larger complete assemblies — and this increased speed to market can significantly differentiate your brand and increase profits.

Building a relationship with an experienced injection molder contributes to shortened lead times and business growth in several key ways:

In addition to speeding time to market, a partnership with high-quality injection molder provides:

There are plenty of challenges in business today. With tight margins, the need for cost control (without sacrificing design creativity or product quality) and value-added partnerships has never been greater. Find out more about how the right partnership can influence your project costs by reading our helpful whitepaper, below.

TL; DR: The 30-second Summary As manufacturing evolves, OEMs are focusing on quali…

READ MORE

TL; DR: The 30-second Summary Non-uniform walls create quality issues because of p…

READ MORE

In many complex industries, decisions about which injection molder to use for cust…

READ MORE