Injection molding process

An estimated 80% of a project’s costs are determined within the design phase.1 For injection molded parts, tooling often consumes a good share of the budget and decision-making, but it’s not the only consideration.

Value-added services (also known as secondary operations) are essential and sometimes overlooked during design because of their injection molding post-processing status. However, identifying the proper value-added services early in the project timeline can help eliminate injection molding defects that could ultimately lead to costly fixes.

Leaning on lengthy supply chains to provide secondary operations carries its own risk. Delayed communication, part quality control, responsiveness, and other essentials can interfere with time to market — and profitability.

Partnering with a custom injection molder that offers in-house value-added services is practical, but not all molders that provide secondary operations are a solution. Finding a molding partner with proven capabilities and the expertise to guide choices on services that suit your project streamlines decision making, risk, and costs.

A leader in custom injection molding, Kaysun views value-added services as more than customer convenience. They are integral to optimizing cost-effective solutions for challenges OEMs face on a daily basis.

Focused on refining injection molding post-processing to true value-adds has led Kaysun to cultivate time- and cost-saving capabilities unmatched by other molders.

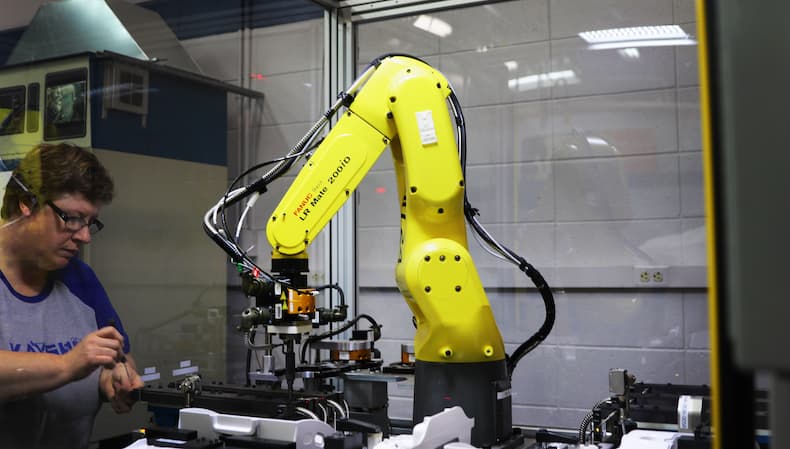

For routine or complex general assembly and part-handling projects, Kaysun utilizes a large network of knowledgeable automation industry leaders.

However, since most custom injection molding assembly is unique and strategic, it’s the in-house value-added services that elevate an OEM-Kaysun partnership, including:

The injection molding assembly process is increasingly sophisticated. OEMs are put in the position of having to invest more time and money to keep pace with need, so reliable molder partnerships take on added importance.

5 Questions OEMS Must Ask Before Partnering With a Custom Injection Molder provides a framework for evaluating molders based on key credentials that determine suitability for your next — and future — projects. Click the button below to download your copy of this quick-reference guide.

SOURCE

1Advice Manufacturing, Value Analysis (VA) and Value Engineering (VE): Definitions and Benefits, Undated

TL;DR: The 30-second Summary As RJG phases out eDart by 2030, Kaysun is proactivel…

READ MORE

Injection-molded parts and products are staples for OEMs in industries ranging fro…

READ MORE

Injection molding is a versatile and precise process, making it ideal for OEMs tha…

READ MORE