Injection molding process

Successful custom injection molding requires process management that’s guided by expertise and precision timing. Tool and process engineers are front-and-center in the product and tool design phases, ultimately making decisions that guide the steps of injection molding. These are necessary to ensure consistent and repeatable manufacturability of defect-free injection molded parts.

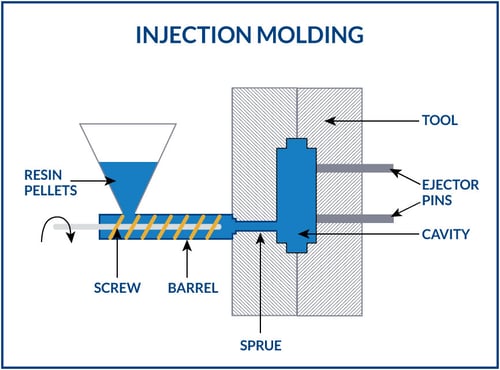

The upfront investment of time and knowledge by the joint team of engineers from the injection molder and OEM is crucial in informing the injection molding process, wherein the product and tool designs are brought together with project-specific resins. Breaking down injection molding step by step illustrates how all phases work together in an injection molding cycle to achieve successful outcomes.

How does an injection molding machine work?

As you've seen, the steps of injection molding are many and complex. To learn more about how specialized engineers oversee each part of the process, download our Scientific Molding guide, below!

TL;DR: The 30-second Summary As RJG phases out eDart by 2030, Kaysun is proactivel…

READ MORE

Injection-molded parts and products are staples for OEMs in industries ranging fro…

READ MORE

Injection molding is a versatile and precise process, making it ideal for OEMs tha…

READ MORE