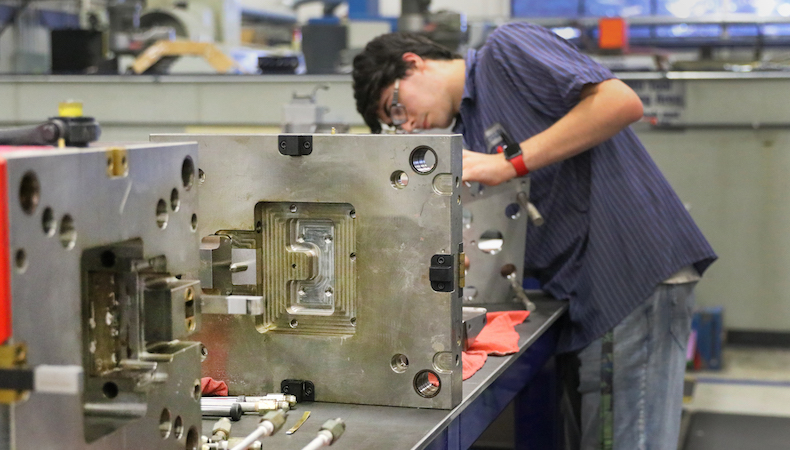

Tooling / Molds

Success in the injection molding business isn’t limited to having the right equipment or the latest technologies. It's a good start, of course, but it takes more to meet the needs of customers that require custom injection molding for complex applications completed under challenging time and cost constraints.

Custom injection molders must have top toolmakers in their supply chains that prioritize manufacturing excellence and customer service. Core to this philosophy is that toolmakers must treat the injection molders’ customers as their own.

Over time (and hundreds of projects), a deep understanding develops between injection molders and toolmakers that underpins partnerships based on:

Having a shared vision promotes opportunities for injection molders and toolmakers to enrich the relationship and help each other improve through:

“We have excellent, long-term relationships with our tooling sources that contribute to pride in good workmanship,” explained Kaysun Senior Business Development Engineer Al Timm. “They have gathered history from past projects about how we want our tools built that they apply to new projects. This insightful working knowledge guides next steps. They know when they can make decisions on their own, and when they need to call us.”

Kaysun has an established, reliable group of “go-to” toolmakers that are familiar with and successful in:

“Our toolmakers are some of the best in the business. They go the extra mile for us when needed,” said Timm. “They also save our customers time and money because they know what quality we expect in a tool which streamlines build lead times.”

It is important for toolmakers to be innovative in their thinking and to stay current with software, hardware, and other technologies. Custom injection molders like Kaysun proactively stay in touch with toolmakers through phone calls, video conferencing, and sometimes on-site visits to establish design approach, approve designs, check the build process, or approve tools for shipment.

This type of teamwork and rapid response to meet customer expectations extends beyond the toolmakers. Vendors that support the tool-making process — polishers, welders, jig grinders, texture houses, and companies that supply tool components — also need to ensure their availability using these communication formats.

Maintaining this solid, reliable network is essential for growing a successful partnership and achieving quality, domestic toolmaking. The process may be slightly more expensive compared to offshore suppliers, but it certainly pays dividends in the long term.

Learn more about the essential role tooling plays in injection molding projects in our white paper, Tooling Design for Injection Molding. Click the button below to download the offer!

Few things impact injection-molded part quality as much as tooling design, materia…

READ MORE

When an OEM pursues an injection molding program, tooling is among the most highly…

READ MORE

Tool design is an essential and sometimes underestimated part of injection molding…

READ MORE