Overmolding

Overmolding is a value-added injection molding method for improving plastic and metal substrate performance and aesthetics. While seemingly simple, the process has a number of underlying complexities that must be carefully considered to ensure your overmolding project meets all goals and expectations.

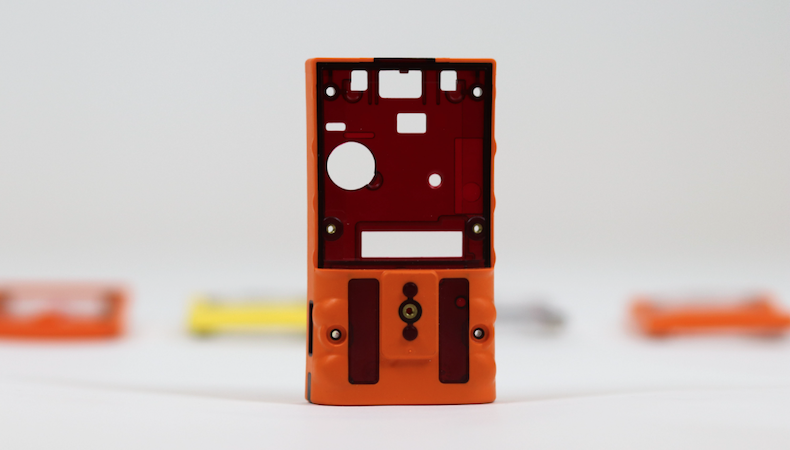

In the simplest terms, overmolding refers to the injection molding process used to add a layer of thermoplastic elastomer (TPE) over a formed metal or plastic substrate for a soft touch, or to join rigid plastics and metals without the aid of glues or fasteners. The substrate provides structural support. The TPE overmold surrounds the substrate to accomplish specific project goals such as augmenting functionality, improving safety, or adding colors for identification and visual appeal. For example, overmolding on portable devices improves grip, increases visibility of buttons and gauges, and protects delicate internal electronics from vibration, moisture, and damage if the device is accidentally dropped.

Overmolding is versatile, and when the process is done by an experienced overmolding molder, it enhances product designs in multiple ways:

Identifying overmolding materials appropriate for a component or device is largely driven by the substrate:

To minimize missteps, molders also work closely with materials suppliers to understand and follow their guidelines during production. However, written documentation of potential compatibility issues is no guarantee of best-in-class results. There is simply no substitute for partnering with an experienced overmolding molder with extensive materials knowledge and a deep understanding of plastic behaviors — including flow, adhesion, and coloration — during molding and overmolding.

Learn more about overmolding principles and how the process contributes to project design, engineering, performance, and manufacturing efficiencies in our whitepaper, Overmolding Fundamentals. Click the button below to access your copy now!

Injection-molded parts are integral to the performance and aesthetics of a wide ra…

READ MORE

Popular across many industries, overmolding may initially appear to simply enhance…

READ MORE

Increasingly popular with manufacturers of consumer products, medical devices, and…

READ MORE