.webp?width=1920&height=1282&name=KSN-how-we-work-with-you-hero%20(1).webp)

How We Work With You

Working with Kaysun isn’t the typical supplier experience. Everything we do is measured against our standard of Engineered Excellence, so don’t expect generic injection-molded parts quotes in response to project requests.

The approach we take to working with you is that of a true partnership, backed by proven capabilities, and guided by our corporate vision:

Kaysun Corporation is the go-to company for positively impacting lives through the products we make and the exceptional experience we provide. Kaysun’s depth of injection molding expertise is matched only by our tenacious pursuit of solutions that align with our customers’ needs, and next-level service and support that consistently earn their trust.

.webp?width=1920&height=1280&name=KSN-custom-injection-molding-certifications%20(1).webp)

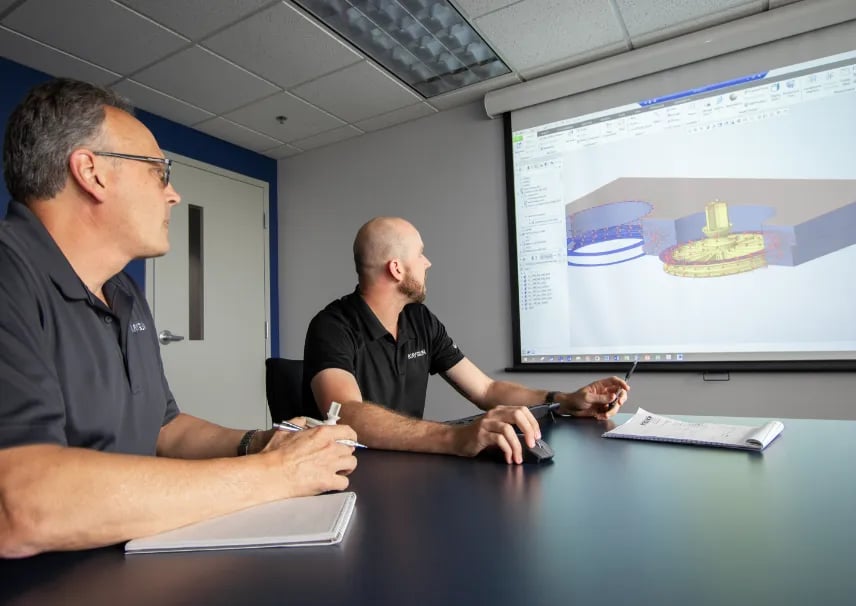

Pre-Production

Understand. Analyze. Collaborate. Kaysun invests in every aspect of your application and engages with your internal teams at every project touchpoint.

We do away with the “You provide a print, we provide a part” supplier mindset in favor of a true cross-functional partnership. The reason is simple: critical evaluation and collaborative problem solving during initial design and engineering means fewer injection molding issues, less rework, and ultimately getting to market faster.

Our engineering team can support your product design and development working with any of your team members.

2-3 weeks on average

Utilizing upfront Design For Manufacturing processes will streamline the product development cycle and minimize time-consuming engineering changes after release.

Pre-production optimizes solutions by refining existing product and manufacturing processes.

Learn More About Our Pre-Production Process

DURING PRE-PRODUCTION, KAYSUN:

- Applies Design for Manufacturability (DfM) analysis, mold flow analysis, and scientific molding software and methodologies to evaluate the application’s tolerances and functional design

- Provides data-based recommendations and seeks feedback on design adjustments for moldability and/or cost-effectiveness

- Guides informed decision-making on material selection, sourcing, and supply chain mapping/management

Pre-Production Processes That Define True Injection Molding Partners

Production

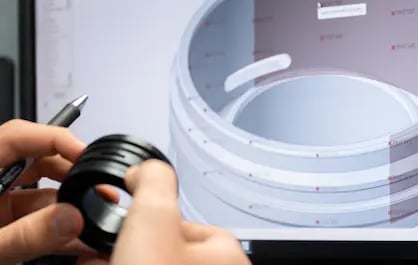

Applying the learnings from the initial part design and engineering evaluations to production processes requires the practicality and skill of an experienced injection molder.

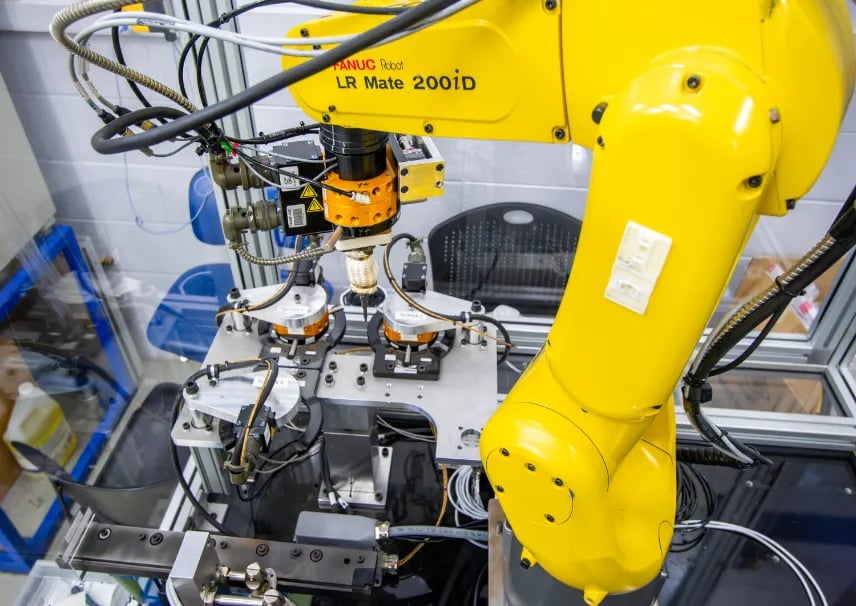

Production must be consistent, repeatable, and accurate to manufacture injection-molded parts that perform to exacting standards. To that end, Kaysun leverages the considerable knowledge and experience of internal cross-functional teams in:

- Tooling that aligns with and is maintained in conjunction with part design, engineering, testing results, and modifications

- Quality control facilitated by certified quality and continuous improvement experts within an advanced in-house quality laboratory

- Value-added services that optimize the production and delivery of cost-effective injection-molded solutions that are higher quality, lower cost, and typically sent to market faster than those manufactured by non-vertically integrated molders

Absolutely, however openness to design and process changes during the transfer will allow for improvements to be implemented.

We utilize local partners to build tools, however we maintain full design responsibility and long term tool maintenance. We do utilize our fully equipped and staffed tool room for ongoing maintenance and engineering changes.

We have presses ranging from 35 ton up to 940 ton, all electric for improved quality and control. We utilize 3 exceptional machine manufacturers, Toyo, Sodick, and Kraus Maffei.

Certainly! You can watch a virtual facility tour, or contact us to schedule an in-person tour.

We develop a control plan and in-process inspections where data can be shared at any time. If additional inspection is required, we can work with your team to support.

Production Processes Only an Experienced Molder Can Offer

Ongoing Support

As the preferred injection molder to a range of industries, we’ve been approached with all types of injection molding scenarios. Our experience, desire to help our customers, and knowledge that there is no standard solution to a unique problem makes Kaysun ready and willing to tackle even your toughest challenge.

Kaysun is built on partnerships, and we take the commitment seriously. We think beyond the injection molding process to how our expertise can influence other critical areas of your business, including:

- On-Time Delivery (OTD) performance that’s reliable and increases the trust of your customers and other stakeholders

- Short- and long-term strategies for sourcing alternate materials during times of global crisis, supplier discontinuation, or other breaks in the plastics supply chain

- Value Analysis/Value Engineering (VAVE) that’s specifically designed to assess design, materials availability and pricing, and production processes to effectively trim costs without compromising part quality or performance

We hold ISO 13485:2016, IATF 16949:2016, and ITAR certifications, and are MedAccred Plastics Accredited. You can view more information on our capabilities, certifications, and areas of expertise here.

We were established in 1946.

Manitowoc, Wisconsin

We support companies throughout the world, including but not limited to Mexico, Germany, Japan, Korea, Turkey, Canada, China, India, Austria, Brazil, and others.

We specialize in complex molding projects

for industries including Medical, Automotive, Industrial, Consumer, Defense, Energy, and Oil & Natural Gas.

We have a wealth of helpful ebooks, white papers, tip sheets, videos, and more for all industries, which can be found on our Resources page.

You can reach out to us on our Contact page.

How Kaysun Approaches Continuous Improvement

3 Proof Points of a Valuable Partnership Only a Trusted Injection Molder Can Provide

Does your company fit our ideal customer profile?

Complete the form to request a free consultation with our plastic engineering experts.