Automation

As Industry 4.0 continues to evolve, the Internet of Things (IoT) takes on even greater importance. Automation and robots for injection molding machines are routinely found — and expected — on production lines as OEMs and custom injection molders lean into the future.

Data and analytics rule the day, and the current trends1 reflect it. Smart technology is instrumental in several facets of production, as they:

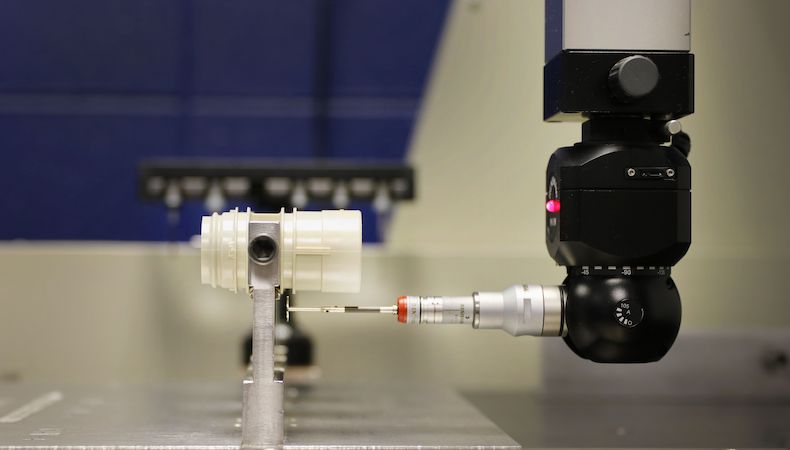

The efficiencies gained through the advent of Industry 4.0 and smart technologies is further enhanced by robots for injection molding machines. Having these versatile tools available in work cells aids in speeding up repetitive tasks like loading and unloading components from equipment.

Time and cost efficiencies increase exponentially as robotics are used in key processes2, including:

Current and emerging trends suggest that custom injection molding continues to advance, benefitting OEMs in all project phases, from design through production and go-to-market strategies.

An experienced custom injection molder with the foresight to see what’s on the automation horizon and incorporate it into their processes is the partner you want – and need – for leveraging Industry 4.0. Learn more by watching our short video, Injection Molding Automation in Action.

SOURCES

1Travelers, 5 Internet of Things (IoT) Trends in Plastics Manufacturing, Undated

2Robots.com, The Robotic Future in Injection Molding, Undated

TL; DR: The 30-second Summary As manufacturing evolves, OEMs are focusing on quali…

READ MORE

TL;DR: The 30-second Summary As RJG phases out eDart by 2030, Kaysun is proactivel…

READ MORE

Despite being considered more energy efficient and producing less waste than other…

READ MORE