Kaysun in the News

- Kaysun Corporation receives MedAccred accreditation!

By receiving its MedAccred Plastics accreditation, Kaysun is now one of only a few injection molders in the United States to hold this certification. LEARN MORE

- 2 Suppliers in the MedMMAP Program Gain MedAccred® Accreditation

Kaysun Corporation was awarded their initial MedAccred Accreditation in Plastics on March 18, 2019, in the area of Injection Molding of thermoplastics and isomers, to include insert molding and overmolding.

- Advancements in Resins Impacting Product Design

https://www.machinedesign.comPlastics have been making leaps and bounds in recent years.

- Designing With Plastics for Military Equipment

https://www.aerodefensetech.com

U.S. soldiers carry loads of equipment and protective gear that can weigh anywhere from 45 to 130 pounds. This is more than enough to quickly tire even the most well-conditioned personnel, contributing to reduced mobility and impaired decision-making that could result in casualties.

- Lower Schuette Park Fitness Zone Opens May 16, Features Equipment Donated by Kaysun Corporation

Kaysun Corporation, in partnership with the City of Manitowoc, is proud to announce the completion of the Lower Schuette Park Fitness Zone, 3800 Broadway St., a section of Henry Schuette Park dedicated to promoting physical fitness among community members of all ages and abilities. READ MORE

- It’s Never Too Early to Select Your Plastics

https://www.machinedesign.comHere are three reasons why engaging with an injection molder early in the design process delivers better results.

- Advanced Plastics Make Tomorrow's Vehicles More Efficient, Affordable, and Attractive

https://www.encmag.comA look at how selecting the right plastic can reduce material and manufacturing costs while improving durability.

-

Complex Injection Molding - What You Need to Know

https://www.medicaldesignandoutsourcing.comWith careful planning, complex injection molding can reduce costs, optimize functionality and improve aesthetics in medical devices.

- Kaysun Corporation $25K gift provides scholarships to LTC students | Manitowoc schools

http://www.htrnews.comLakeshore Technical College Foundation recently received a gift of $25,000 from Kaysun Corporation of Manitowoc to provide scholarship support for LTC students.

- Top Five Benefits of Injection Molded Parts for Electronic Medical Devices

http://www.encmag.com

Medical grade polymers are becoming the preferred material for a broad range of electronic medical devices. This is because of their versatility and ability to either completely replace metal, or combine with metal to create an enhanced product with attributes that would otherwise not be possible. Kaysun unpacks the top five benefits to using complex injection molding for electronic medical devices.

- Metal to Plastic: Design Flexibility

http://www.asme.org

Converting existing products or parts from metal to plastic reduces the weight and cost of manufacturing. Kaysun explains how the design flexibility of injection molding can be used to replace multiple metal parts with just one.

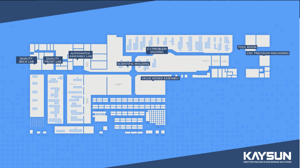

- Mold Design & Tooling for Injection Molding

http://www.encmag.com

The precision and complexity involved in injection molding is known to many manufacturers. Kaysun’s step-by-step explanation of designing the mold and its various components, known as tooling, highlights the company’s expertise.