Medical

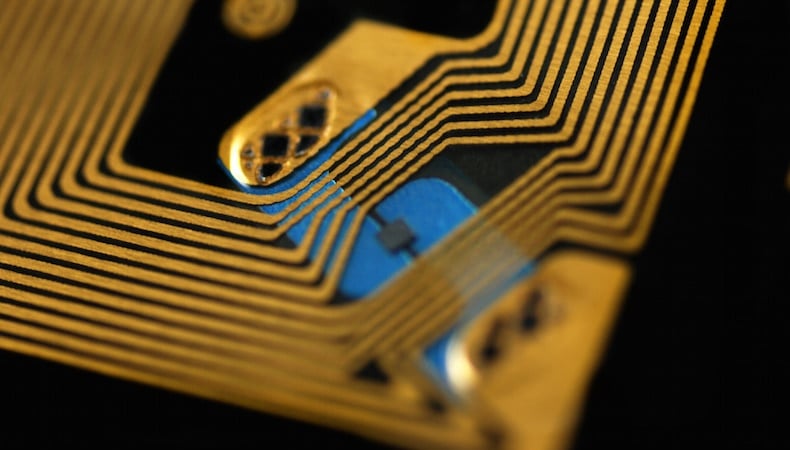

Though most commonly known for use in retail operations, radio-frequency identification (RFID) technology has also made a big breakthrough into pharmaceutical circles—and more recently, with medical devices. In 2016, there were more than 8 billion ultrahigh-frequency (UHF) RFID tags sold worldwide, with only 60% going towards retail. RFID tags typically operate like barcodes, sending out radio frequencies to special reader devices, where data from the tag is captured and stored in a database. With medical RFID applications, however, the uses go way beyond the barcode, and can help medical device manufacturers improve processes and deliver a better final product.

For OEMs looking to stay at the forefront when it comes to the latest medical and supply chain technology, keep an eye on these three RFID tech trends gaining popularity in the healthcare industry today:

With sterilization being crucial in hospitals and other medical facilities, Johnson & Johnson has developed an Advanced Sterilization Product (ASP) to help ensure that medical objects stay sterile in such places. This hydrogen peroxyde, low-temperature smart sterilization chamber uses RFID technology to identify connected components and commodities, identify samples in a centrifuge, and provide secure staff authentication for access to machines and devices. In a world where sterilization issues continue to cause problems for hospitals, the new RFID technology has helped create a feeling of certainty.

In addition to the RFID uses above, one of the main functions of RFID in an ASP is for compliance control on the chamber’s cleaning and reprocessing protocols. Every hydrogen peroxide cassette within the chamber is embedded with a high-frequency RFID tag, which helps identify and report alerts while signaling for maintenance. Likewise, the RFID tags help ensure that the cassettes comply with ANSI/AAMI/ISO standard 14937:2009, giving full confidence to hospitals that their medical objects are completely sterilized.

The data that can be stored on today’s RFID tags is very helpful to OEMs and end users like hospitals when it comes to inventory management. A data set like lot number, manufacturing date, shipping date, date of sterilization, and even treatment history can be stored on a device’s tag, and the technology can provide the ability to individually identify tags in large batches, even inside boxes. The data can show what’s in storage (and where), what’s currently being used, as well as alert you when it’s time to discard to a product. The ability to do all these things quickly also helps save valuable time, resources, and effort, while improving accuracy.

While there’s been some worry that electromagnetic emissions from RFID tags could interfere with medical devices, the FDA has made it clear that there are no known adverse effects from the use of RFID in medical applications. RFID technology has become crucial for helping improve the processes of medical OEMs and the functionality of their new products, with more new uses and applications surely on the horizon.

To learn more about what it takes to produce plastic components for reliable, high-quality medical devices and equipment compatible with today’s new technology, make sure you read our Scientific Molding in Medical Device Manufacturing white paper — click the button below to read it now.

MD&M West is one of the largest and most respected medical device trade shows …

READ MORE

When you operate at the top of your game, reach higher. Kaysun had already shown i…

READ MORE

Kaysun's commitment to excellence is well documented through its certifications, i…

READ MORE