Plastic part design

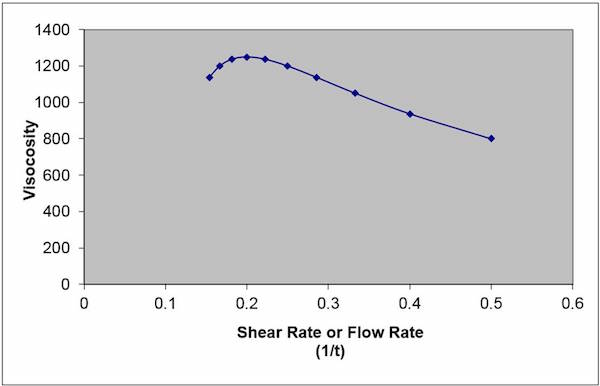

For engineers specially trained in scientific molding, a DOE matrix is key in decision-making since it reflects the sum and substance of the entire DOE process. DOE gathers statistical evidence through multiple measurements and balances them with external influences to run analysis and construct a mathematical model, as illustrated here:

Sample DOE graph

However, this deeper learning isn't math for math's sake. A DOE experiment allows engineers to accurately retrace steps, resolve any contradictions, and determine next steps — either recommended changes or further required testing.

DOE gives custom injection molders the ability to find the ideal process window, and better understand the result of having and maintaining it. The mathematical accuracy with which DOE displays the relationship between values and ideal outcomes is fundamental to scientific molding on the whole, and also to three key injection molding project goals:

Product and/or process design sensitivities and potential changes are revealed when DOE evaluates factors sometimes overlooked by product engineers — such as materials and injection molding settings (injection speed, melt temperature, cooling time, etc.).

The thorough process raises questions about their influence on design and fulfillment of project specs. As a result, corrective adjustments to input values or other standards can be made to ensure expected performance.

Using DOE during plastic injection mold design minimizes poor design prior to manufacturing since the process outcome is verified. It also can prevent faulty plastic part designs from inadvertently reaching the production floor, as testing can reveal which manufacturing changes need to be made to correct missteps. This allows manufacturers to optimize their time and resources at every production step.

DOE is versatile and can be applied to gather data about the ability of plastic parts to withstand any number of environmental conditions. This granular knowledge reveals design flaws and potential failure risks, providing ample time for modifications that translate to better, more reliable products going to market.

DOE is a scientific molding imperative and a mathematically precise way to ensure best outcomes of plastic injection molding projects for customers, manufacturers, and end users. Learn more in our white paper, An OEM's Guide to Scientific Molding. Click the button below to download your free copy.