Value-Added Services

Working with vertically integrated key suppliers does more than provide access to multiple value-added services. Communication, product quality, cost management, time to market, and responsive adjustments to market shifts all improve, as does supply chain risk mitigation.

Post-mold value-added engineering services (aka, secondary operations) optimize Kaysun’s ability to deliver cost-effective solutions to complex manufacturing challenges. The breadth of in-house services offered — welding, heat staking, machining, testing, identification technologies, and packaging — cover the full part or product life cycle, from design through assembly and packaging.

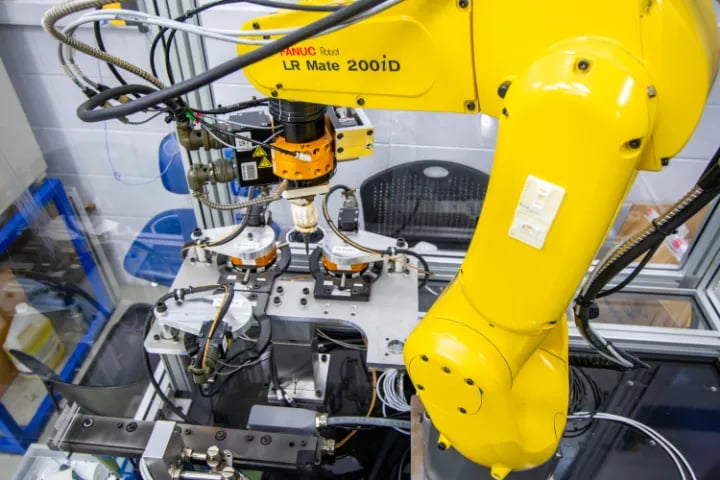

In-House Injection Molding Automation

Depending on customer and application needs, assembly of components can be by hand or through automation, and performed in standard or cleanroom conditions.

Kaysun’s value-added services and customized assembly options result in highly efficient design, engineering, and manufacturing processes that save time, reduce costs, and help get products to market faster.

Ask Our Experts Questions? Comments? Next Steps?

Our team is here to listen — and help!