How Injection Molders Help Manage Project Timelines, Specs, and Budget

Defect-free, low-cost critical use injection molded parts are the intended result of any project. But, how do you get from start to finish and remain on time, on spec and on budget?

If you strategically build a partnership with an experienced injection molder – and incorporate their expertise and capabilities throughout the process – you’re well on your way to project success.

On Time

Your partnership with a molder saves time upfront and in the future. In fact, a comprehensive Design for Manufacturability (DfM) analysis can save up to two months in tooling and prototyping iterations.

This amount of breathing room can supplement any buffer time you might not have planned into your complex injection-molding project to allow for errors and corrections. In turn, less rush means less likelihood of errors and derailed timelines.

On Spec

When you engage with a complex injection molder in the design phase, you’re setting your project up for success. You’ll have the benefit of the molder's expert plastics engineers to guide quality control using important processes for efficient and economical manufacturing.

Scientific molding, for example, is a discipline that helps achieve optimal control of the injection molding process by developing templates for repeatable production, and delivers faster molding cycles and higher yields. In order to remove guesswork from the injection molding process, specialized engineers oversee and analyze data in each phase:

- Tool build and debugging: Implementing the scientific molding process in full by testing to define parameters and record data for template creation

- Production: Diligently monitoring production against the template to identify and resolve any issues

Engineers who are experienced in complex injection molding also review the following to ensure quality of your plastic components, and ultimately your end product, from front-to-back:

- Component design: Assessing your needs and requirements for the intended component, and identifying the best approach to achieve them, including polymer selection, gating design, corner radii, draft and wall thickness

- Tool design: Vetting the overall mechanical design of the mold from steel type, gate location, venting and cooling channel layout and ejector pin locations

- Assembly: Performing dimensional checks to ensure repeatability across multiple production runs

On Budget

Budget is always a key consideration, and complex injection molders are prepared to help you save money. Their insight about the specific project’s design and production results in:

- Fewer design errors, and less overall production expense

- Less retooling, and opportunities for correction well before manufacturing

- Consistent repeatability, and control of future costs

Plus, complex injection molders have specific capabilities that impact the bottom line of complex, critical use parts like:

- Materials expertise that aligns polymer performance characteristics with strength, flexibility, temperature and impact resistance needs

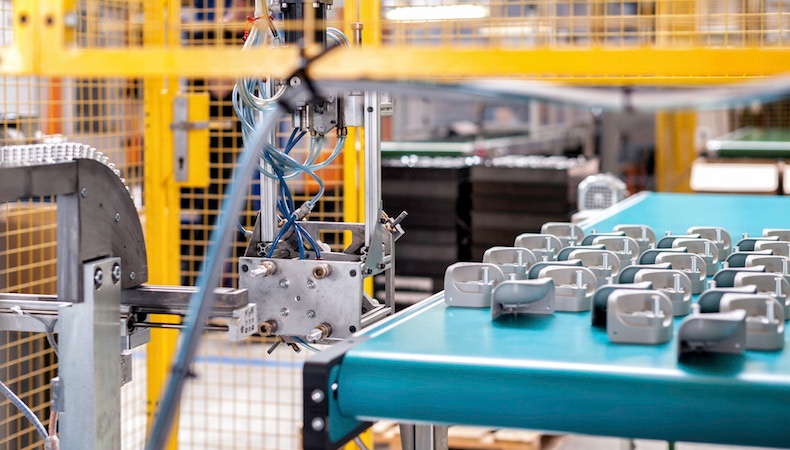

- Robust equipment that provides high precision and tight tolerances needed for complex, critical-use injection molded parts

- Adaptability that keeps short lead times and tight production schedules on track

A complex injection molder – especially when involved early in your project – helps balance deadlines, quality and cost objectives. Learn more by reading our helpful whitepaper, below.

Subscribe

TO OUR BLOG

How Do Injection Molder Partnerships Influence Project Costs?

You Might Also Like...

4 Factors That Reveal an Injection Molder’s Plastic Engineering Bandwidth

There’s no one indicator that points to a custom injection molder’s readiness and …

READ MORE

The Bottom Line on Custom Injection Molding TCO vs. Per-Part Quotes

Complex applications typically require custom injection molding solutions. It’s an…

READ MORE

How to Design for Sustainable Injection Molding: Values, Materials & Processes

Sustainability is an increasingly urgent concern for businesses. On one hand, cons…

READ MORE